Settings of TNT parameters

In general, errors in setting the aforementioned parameters can compromise the quality of the final reels, or even prevent the winding operation. Among the main defects we can find:

- Telescoping or non-cylindrical shape, symptom of insufficient compactness due to excessive trapping of air between the reels;

- Collapse of the core or gluing of the single coils, due to excessive compactness;

- Starring, due to an uneven increase in tension as the diameter of the reel increases;

- Taper effect, that is the phenomenon whereby as the diameter of the reel increases, the innermost layers are crushed by the external ones due to excessive tension;

- Stretching of the sheet and a consequent excessive reduction of the width of the final reels, for materials with elastic properties;

- Loss of volume and bulk, in case of excessive compactness in the reels of creped products

Machine Cycle Time

Problems of poor speed and productivity can be caused by the lack of optimization of the machine cycle times, such as the master roll change operations, knife positioning, finished reel change, defect management and in general all the operations that take place when the machine is stopped.

Slitting

As for nonwoven and elastic materials, the setting of the slitting width must consider the phenomenon of the neck-in, that is the elongation of the material when the cut strip is subjected to traction in the Machine Direction by means of the carrying drums and wound around the cardboard core. In addition to this, attention must be paid to possible problems of radial or axial eccentricity, vibrations, cutting angle, lateral load and wear of the blades.

Presence of slitting dust and other contaminant agents

For hygienic products, it is essential that the dust created during the various rewinding phases is sucked up by means of special systems to prevent possible contamination. Other contaminants to watch out for during the winding and rewinding process can be dust, grease or oil.

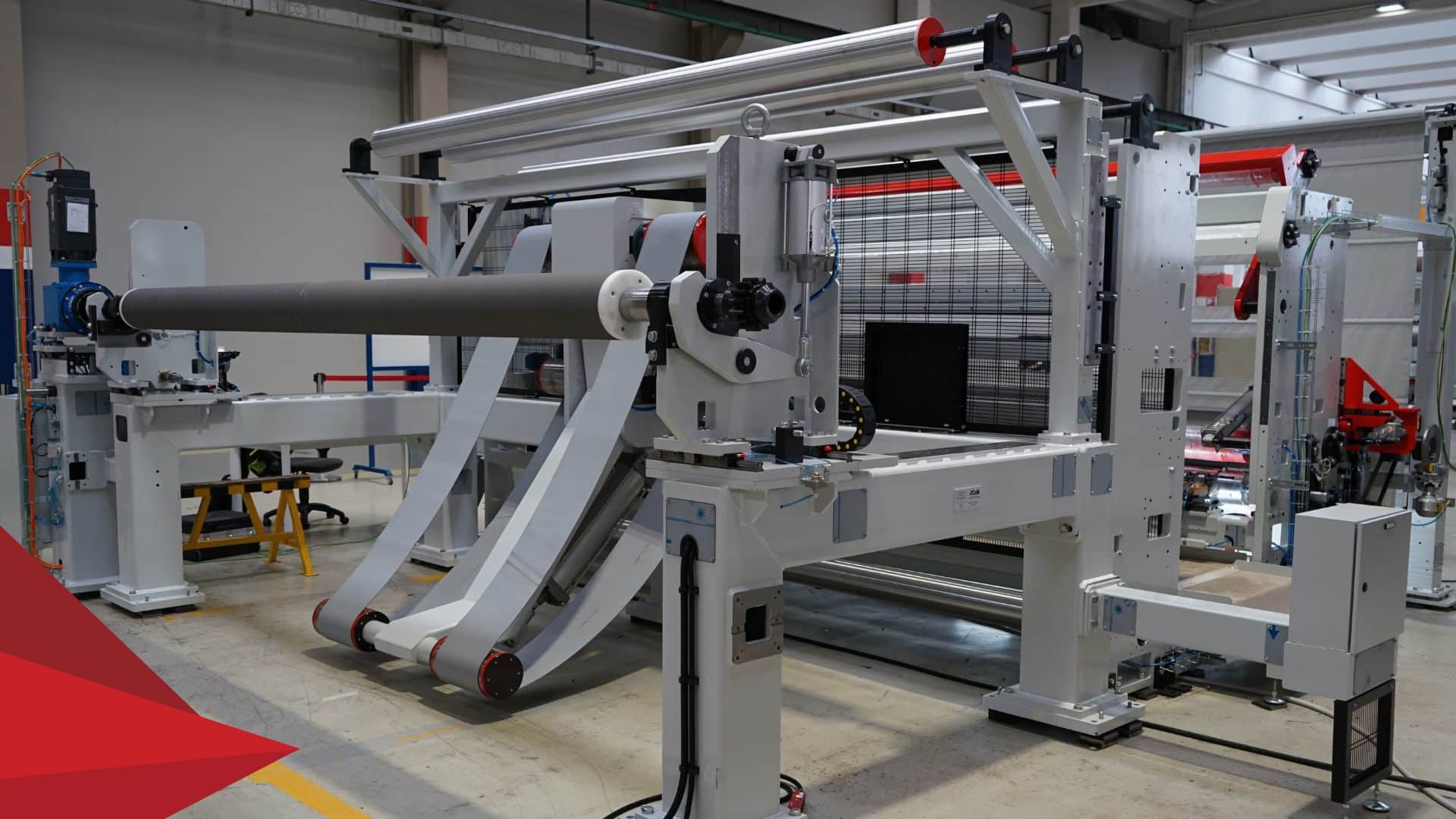

We can deduce, from these issues, how many variables are that must be kept under control to produce a high quality paper, tissue or nonwoven reel. For this reason A.Celli has created E-WIND®, a range of products dedicated to winding, unwinding and rewinding capable of guaranteeing extraordinary performance, flawless finished reels, high automation capabilities and ease of control and use.