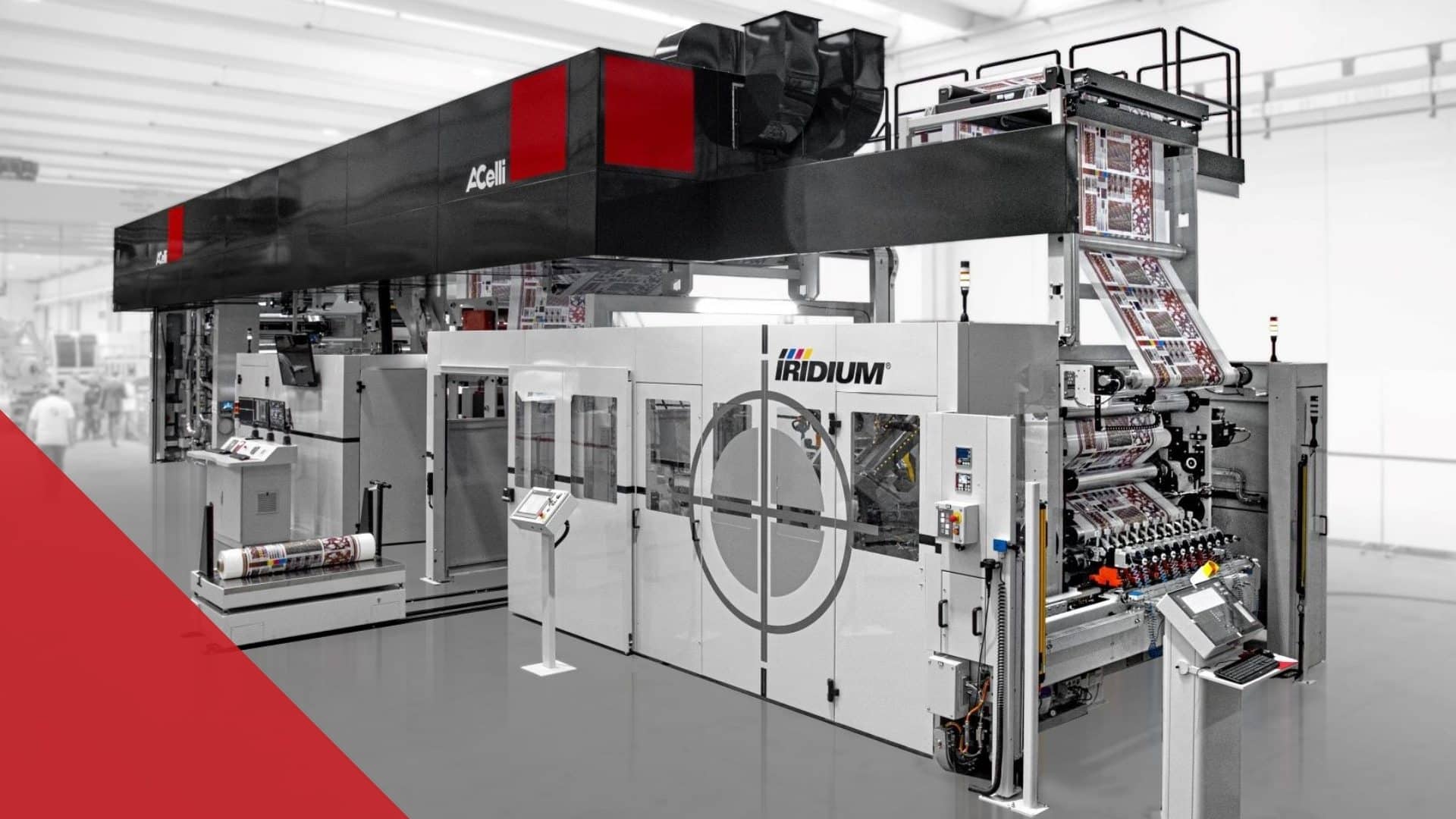

Center Turret winder versus Surface-driven winder

To rewind the printed and slitted material, thus obtaining the final reels ready to be sent to the converter, we can use center turret or surface-driven winders.

The center turret winder is characterized by a center-driven winding process: when the the desidered diameter of the reels is reached, the winder will rotate, positioning the new core in place of the reels just wound to allow both the winding of new reels and the unloading of the finished ones.

The problem that arises using this type of machine is that, from the beginning of this rotation to its end, the newly wound reels continue to drag the material during their repositioning. This leads to a loss of the correct tension of the material ensured by the dancer roller, and this will cause the reels to overlap each other. Result: this stretch of material, which is around 400 meters given that the center turret rewinder takes on average 35 to 40 seconds to perform the rotation, will have to be cut and discarded from the final reels before the packaging, storing or shipping to the converter.

This problem is solved with the use of a surface-driven winder like the A.Celli Nexus. With this solution the winding package is loaded against a driven drum equipped with a high grip coating, and the power necessary to rotate the package is transmitted from the outer surface of the drum itself. This will allow the elimination of the aforementioned waste of material resulting from the use of the center turret winder.

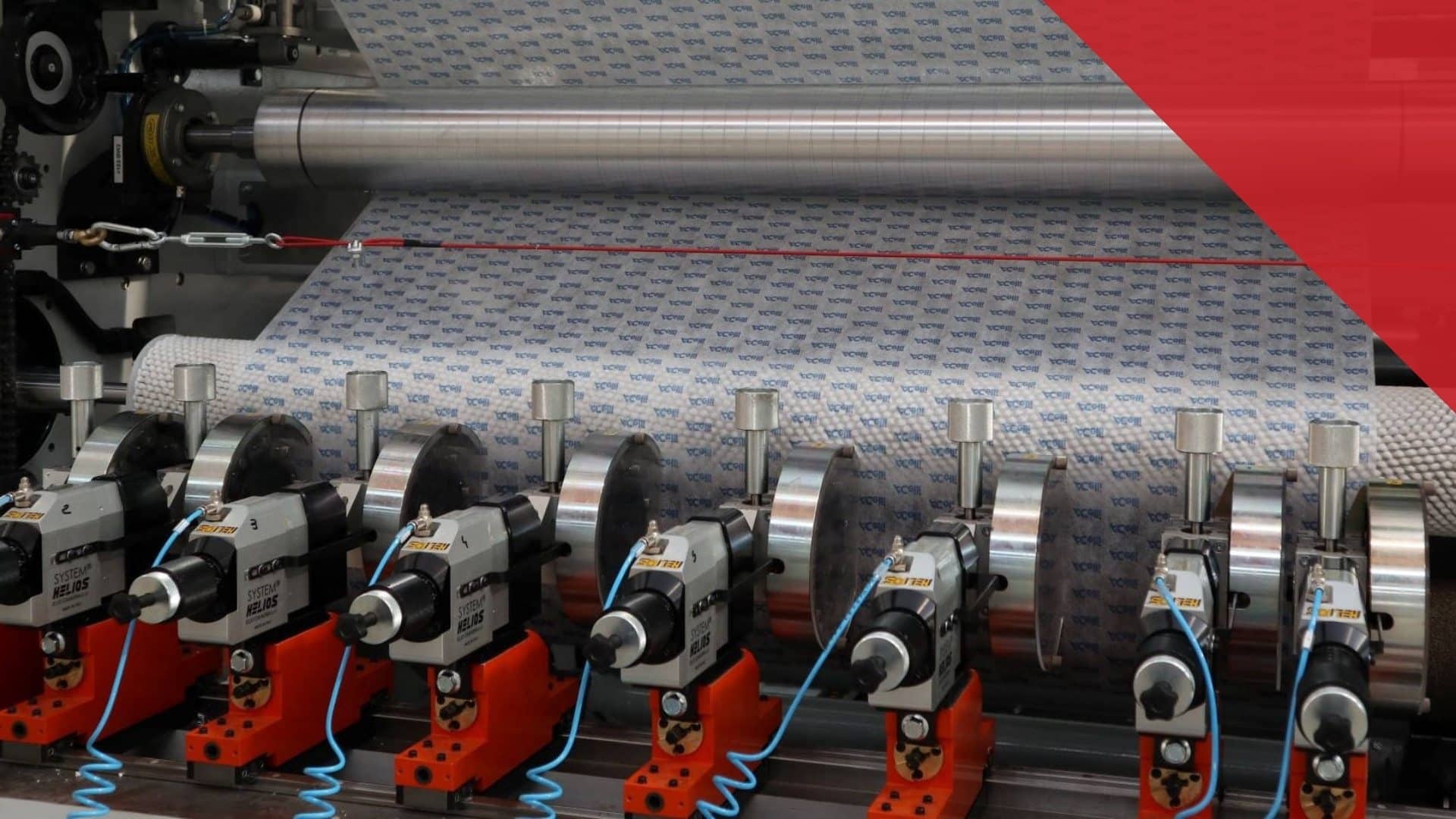

Automatic knives positioning system

In the hygienic industry there is often the need to print a pattern with a certain repeat length and the image centered in relation to each of the reels obtained with the slitting process. When no automation process is implemented, the knives of the slitting group must be manually positioned.

In this case, If the printed reel must be slit into a certain number of smaller reels, each of the knives has to be positioned by hand with extreme precision to ensure the image is centered in each of these reels. Achieving this is very difficult: if the knives are poorly positioned even by one or two millimeters during the slitting, the image will not be centered in some of the reels, leading to a waste of material, time and, consequently, money.

This without considering the neck-in error, which happens when the material is pulled, and thus shrinked, during processing. With manual operations, obviously, is extremely difficult to calculate how this error will affect the final result and therefore position the knives accordingly.

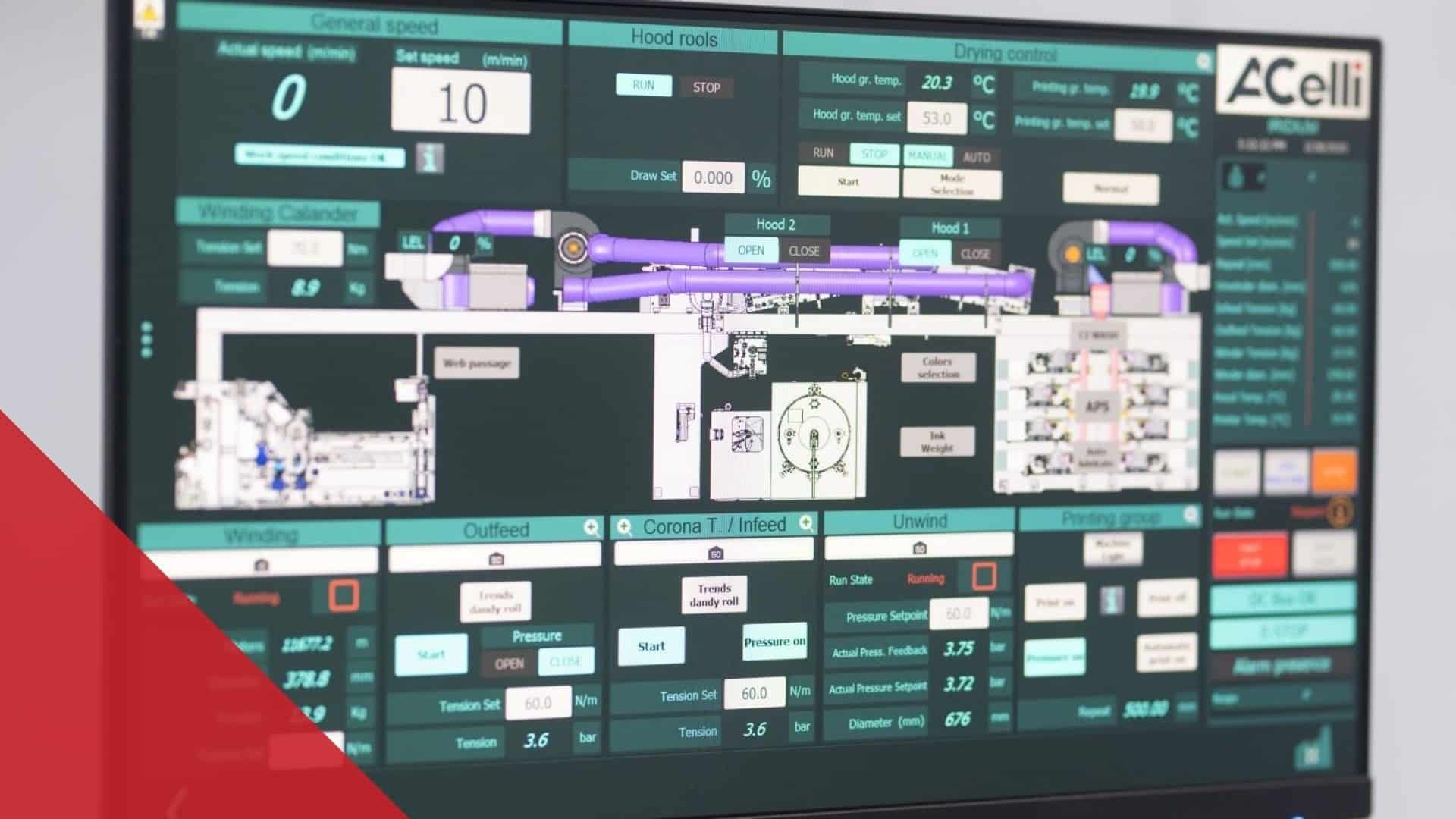

The A.Celli Slittomatic® system has been designed to solve these very problems. Our solution is an advanced system that will ensure a fast, accurate and completely automatic knives positioning. Moreover, thanks to our system, the knives positioning will be performed at the same time as the setup of the print job (colors registration, printing pressures etc…), which is impossible to do with manual operations. This will ultimately save you time and further reduce material waste, resulting in a high quality, defect-free product with no additional downtime.

If you would like to know more, contact us today for additional information on A.Celli solutions for flexo printing!