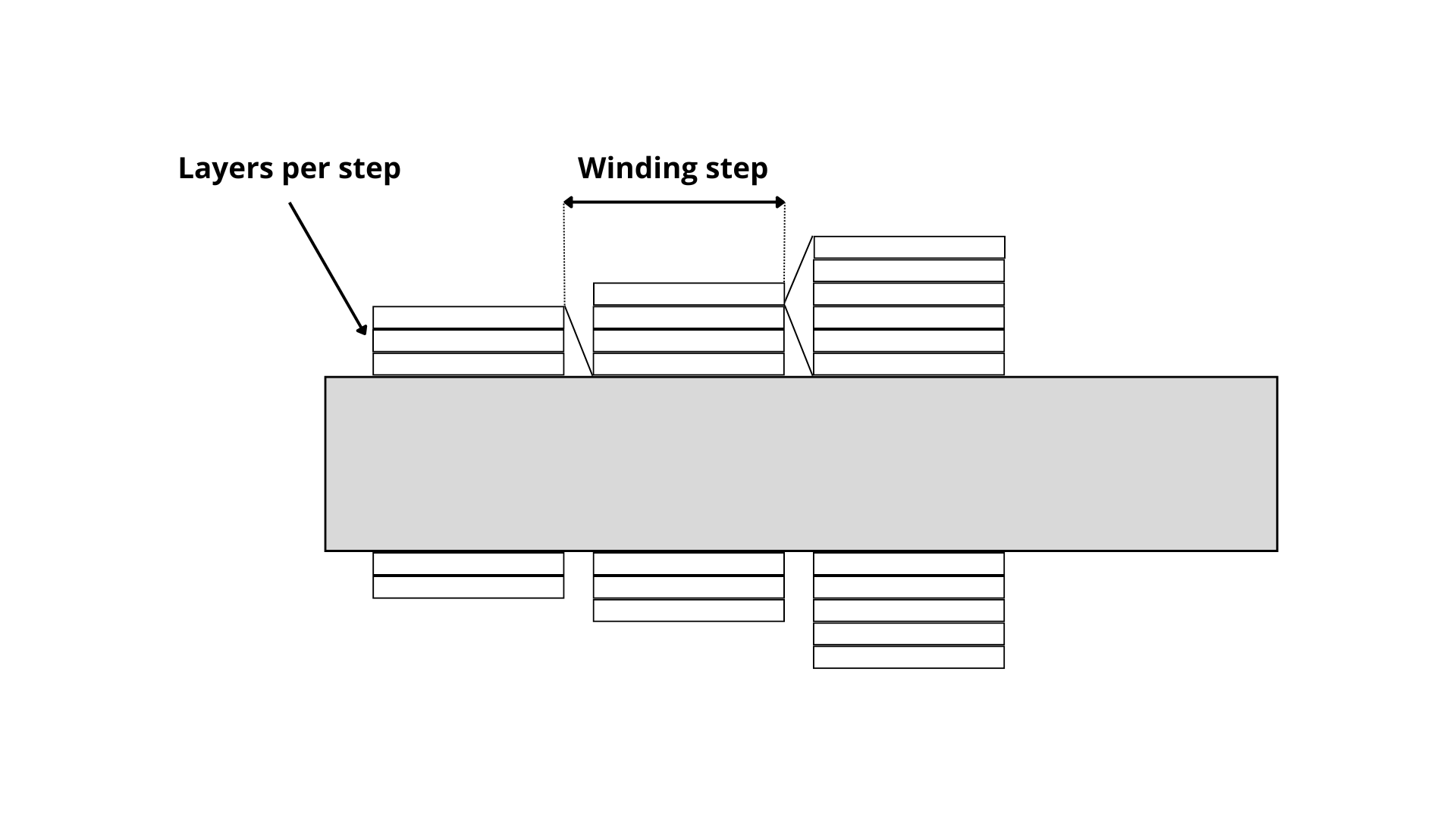

One of the most significant advantages of step winding is its ability to reduce mechanical stress on delicate materials. The decreased lateral movement ensures that sensitive nonwoven fabrics do not experience excessive stretching or tension, which can lead to deformation or instability. This feature is particularly useful for materials that retain a “memory” of their winding process, as step winding helps preserve their structural integrity during unwinding and further processing.

Another key benefit of step winding is its capacity increase the density of the finished reels. Since there is minimal overlap between winding sections, more material can be packed into the same spool volume compared to traditional traverse winding. This results in longer continuous runs, reducing the frequency of machine stoppages for reel changes and ultimately enhancing operational efficiency. Additionally, the structured alignment of multiple winding sections provides greater spool stability, significantly decreasing the risk of telescoping, where layers of material shift or collapse during unwinding.

Despite its advantages, step winding is technically demanding and requires high-precision machine control to execute seamlessly. The transition from one winding section to another must be swift and accurate, ensuring a clean, defined separation between adjacent layers without unwanted overlap. This necessitates advanced automation and real-time tension control mechanisms to maintain a consistent and reliable winding process. Given these complexities, only high-performance spooling systems can effectively support step winding without compromising production speed or quality. System like the A.Celli F-LINE® Spooling.

A.Celli’s F-LINE® Spooling: Unmatched Flexibility

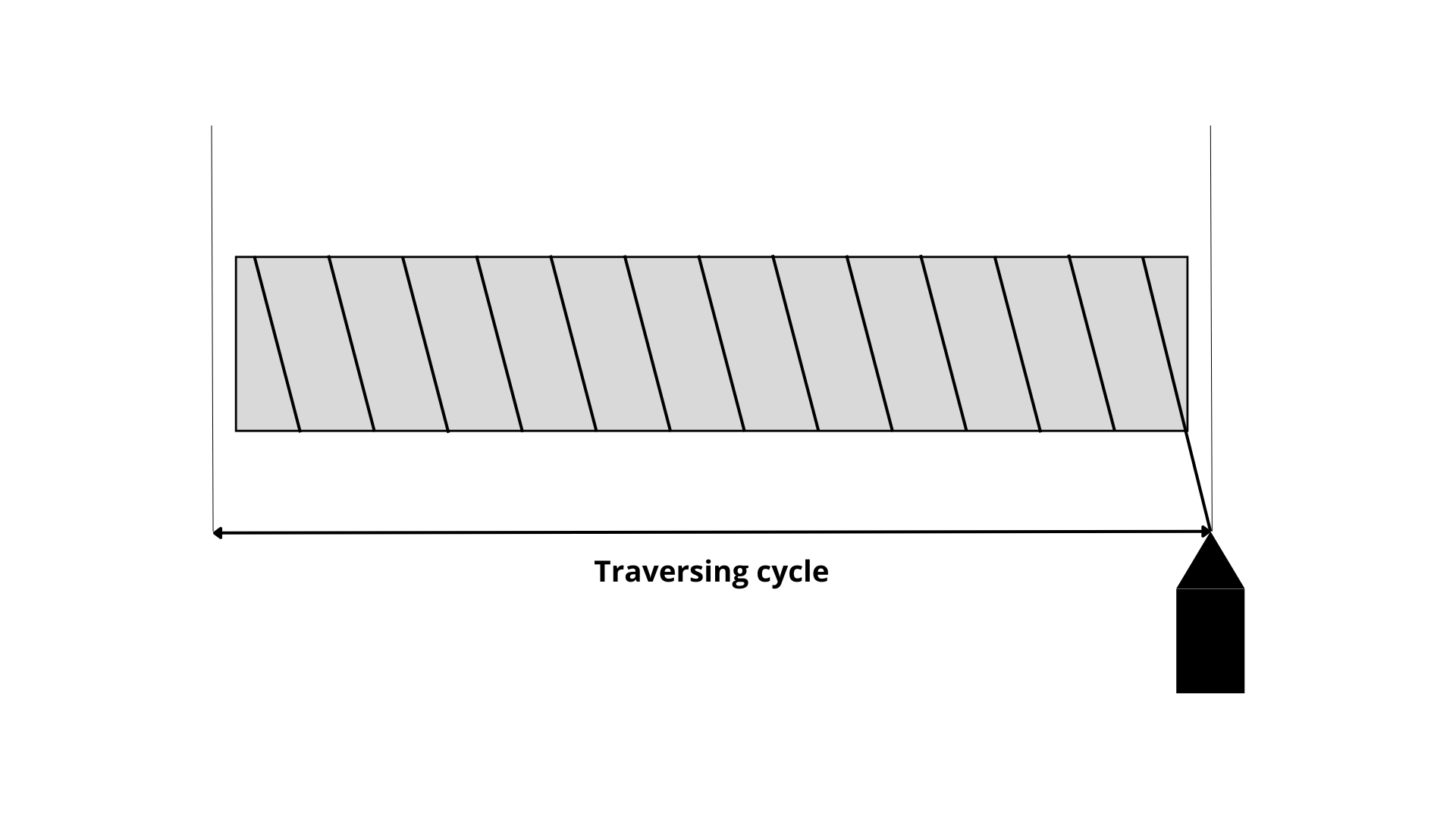

Understanding the need for flexibility in nonwoven manufacturing, A.Celli has developed the F-LINE® Spooling system, a state-of-the-art solution that seamlessly supports both traverse and step winding. This capability ensures that manufacturers can select the most appropriate winding technique based on their specific material requirements and production goals.

The A.Celli’s spooling system is engineered to handle a broad range of applications with precision and efficiency. It accommodates basis weights ranging from 15 to 200 gsm, with finished spool widths of 400 to 850 mm. Operating at speeds of up to 800 m/min, it can support up to 12 spooling heads, making it one of the most advanced solutions available in the industry.

What sets the F-LINE® Spooling system apart is its array of cutting-edge features designed to optimize performance. The dual shaft unwind stand ensures a continuous and smooth material feed, while the ultrasonic splicing and ironing systems facilitate seamless transitions between two master rolls during unwinding. The incorporation of low-inertia carbon fiber idle rolls minimizes friction and enhances the precision of the winding process.

Additionally, the line includes an automatic web guiding system to maintain perfect alignment throughout production and a shear tangential slitting system which enables precise cutting, crucial for achieving consistent spool quality. Furthermore, tension and nip control with a taper function ensure optimal material handling, preserving the integrity of the wound product.

The versatility of the F-LINE® Spooling system makes it ideal for a wide range of nonwoven materials, including bulky products such as ATB, ADL, High Loft, and Air Laid. By offering both traverse and step winding in a single, high-performance solution, the A.Celli’s spooling line provides manufacturers with the flexibility needed to optimize production efficiency, enhance product quality, and reduce material waste. Its adaptability ensures that businesses in the nonwoven industry can achieve superior results, regardless of their specific material and application requirements.