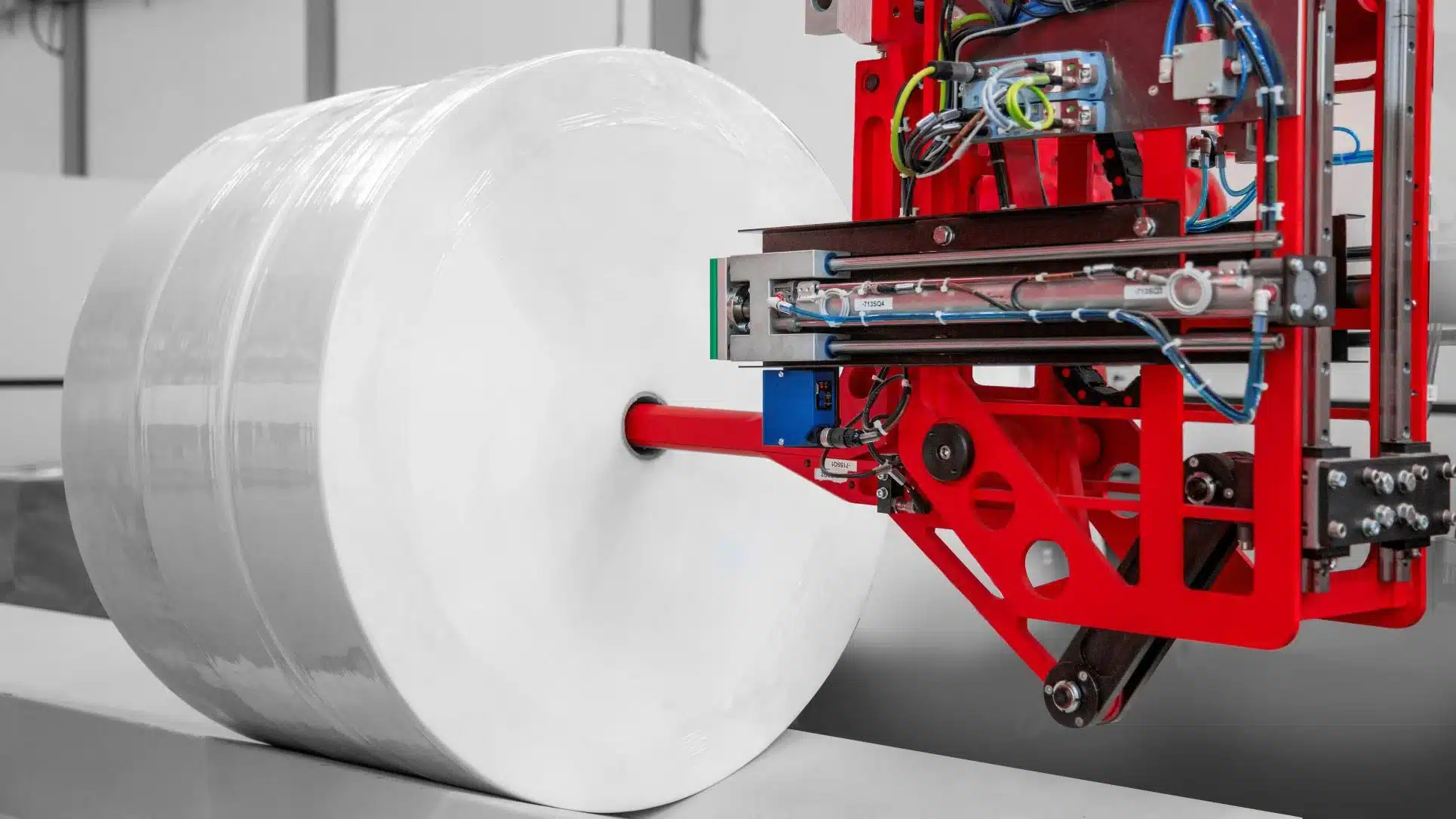

A solution for all packaging needs: A.Celli R-WAY®

The distinguishing feature of an efficient automatic packaging system is the ability to adapt to individual business needs: that is, it must be versatile and customizable. It is in fact the ability to fit into each production line, integrating at best, which allows for optimal results.

These are the characteristics at the base of the A.Celli R-WAY® automatic packaging system, a modular, flexible and efficient solution able to cope with any workload, adaptable to any layout or production line and manageable by a single operator.

Having a customized automatic packaging system means having a system capable of operating at its best, without bottlenecks or inefficiencies. This is because there is an optimal management of workloads obtained thanks to a perfect concordance between production and packaging: both are calibrated on the same production volumes.

More in detail, the R-WAY® packaging system can automate all of the following operations (or, if necessary, only some of them), limiting the possibility of human error and contamination of the reels as much as possible:

- Transfer of the reel from the production line

- Packaging of finished rolls

- Reels and cores labeling

- Bundles labeling

- Weighing of the reel and bundles

- Vertical, horizontal or coocon packaging

- Possible palletization and second packaging

To achieve maximum process efficiency, the best possible quality of the final product and trace each processing step, focusing on automatic packaging is an excellent choice. In fact, it means using the best solution available to ensure that the reel reaches the end customer exactly as it left the production line.

Do you want to find out more about the complete range of A.Celli solutions for the end of line? Download our free eBook “A.Celli end-of-line solutions for nonwovens production”!