3 ways green retrofits will help you save energy

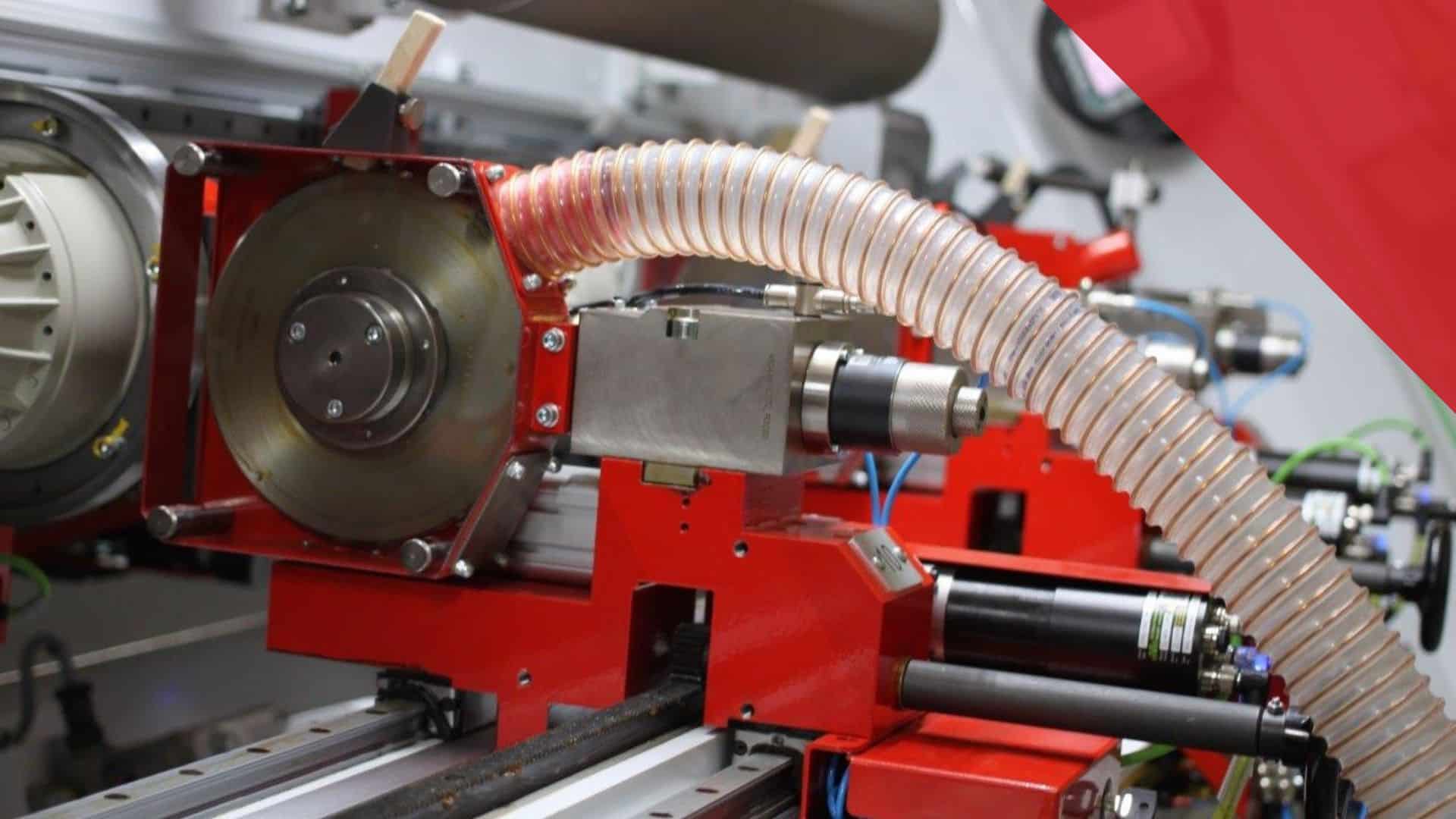

Reducing energy consumption is one of the best measures that any plant can take in this regard. Motors that drive belts, unwinders, winders and other machinery are particularly energy-intensive.

With this in mind, what follows are the ways A.Celli can help your company save energy.

1. High-efficiency motors HELP reduce energy waste in manufacturing processes

An astonishing 74% of the energy consumption in the industry sector is due to the operation of electric motors. Many nonwovens plants are still operating with legacy equipment and machinery equipped with motors that require high energy usage to operate.

Therefore, a green retrofit must start with the replacement of older motors with modern, high-efficiency ones. The use of these motors provides the following benefits:

- Reduced magnetic stress

- Bigger core assembly

- Reduced winding resistance

- Improved bearing and fans

Keep in mind that the cost of an electric motor over its lifespan is greater than the cost of the motor itself. Over the lifespan of the motor, the costs break down as follows:

- 0.3% for maintenance

- 4.8% for the initial purchase

- 94.9% for energy consumption

While it’s true that an energy-efficient motor costs 40% more than the standard electric motor, its energy savings are so high, the result is the investment is paid off in 1.5 years.

It’s also important to remember that maintenance on older motors can be challenging because it is often difficult to find the required parts for it, and keeping machines offline for an extended period of time will greatly affect production and ultimately your bottom line.

2. Industry 4.0 monitoring systems to be aware of your consumptions in real-time

Another important aspect is to ensure energy monitoring is part of a plant’s green retrofit. The goals of this monitoring include:

- Measuring electricity consumption

- Measuring pneumatic consumption

- Evaluating energy allocation

- Conducting Big Data analysis

The best retrofit for energy monitoring involves taking advantage of Industry 4.0, which allows for the automatic, real-time monitoring of energy settings and other machine settings.