How to properly perform flexographic printing and subsequent lamination for hygiene products

If you want to print a plastic film to be subsequently coupled to a nonwoven substrate through lamination, in addition to ensuring a high print quality of the desired motif, it is essential to establish, set and maintain the print repeat length of the pattern to be reproduced.

A variation of the print repeat length, i.e. the distance between two same points in two contiguous images of a pattern, outside the predetermined tolerance will in fact give rise to non-conforming reels to be rejected, with obvious losses (even more significant if these reels are incorrectly subjected to the next lamination process). Therefore, the following factors become fundamental:

- Tension control: apply correct tension values based on the specific substrate and processing phase before, during and after the printing process (including the winding and lamination phase, which could alter the previously obtained print repeat length)

- Structural stability of the printer: the result of an accurate balance between all the parts, both mechanical and electronic, of the machine.

- Air temperature: during the ink drying phase, it is necessary to set an air temperature such as to achieve the desired result without damaging the printed substrate under tension.

- Management of the printed reel aging: by virtue of the elasticity that characterizes the non-woven fabric, with the passage of time the printing pitch tends to lengthen in the outer coils of the printed reel. A similar phenomenon can also occur after the roll lamination process itself.

Once the printing has been carried out and we reach the lamination phase, it is necessary to ensure that the chosen bonding sytem does not damage the materials to be coupled and that the tension values of the aforementioned are adequate in relation to each other, in order to avoid the formation of a defective composite.

A.Celli IRIDIUM® and F-LINE®: the ideal solutions for printing and lamination

From the extensive knowledge of the hygiene sector and of the processing problems to be faced in order to obtain a high quality final product, A.Celli has decided to provide its customers with the means to allow you to achieve the desired results.

Thanks to the IRIDIUM® flexographic printer, A.Celli is in fact able to:

- Optimally control and manage the print repeat length throughout the production process, thanks to solutions such as the interactive print repeat length adjustment system and the Slittomatic®, i.e. a system for automatic positioning of the slitting units with respect to the printer.

- Ensure correct tension throughout the entire printing process through dynamic tension control of the thinnest materials.

- Eliminate the problems that can arise during long print runs.

- Substantially reduce waste during the setup phases (which on average lead to discarding 350 m of product at a time) and printing.

- Enable efficient drying of water-based inks, regardless of the print operating speed (600 mpm and above).

As for lamination, on the other hand, we can identify a series of ideal characteristics that a lamination line should possess, namely:

- Reduced change times

- A solid and robust construction

- Several control areas and a quick setup

- Unwinders and rewinders equipped with double stations to allow the reels to be changed while the machine is running

- A centralized control panel with business intelligence and data collection capabilities

- A pneumatic edge guiding system for unwinding and/or rewinding

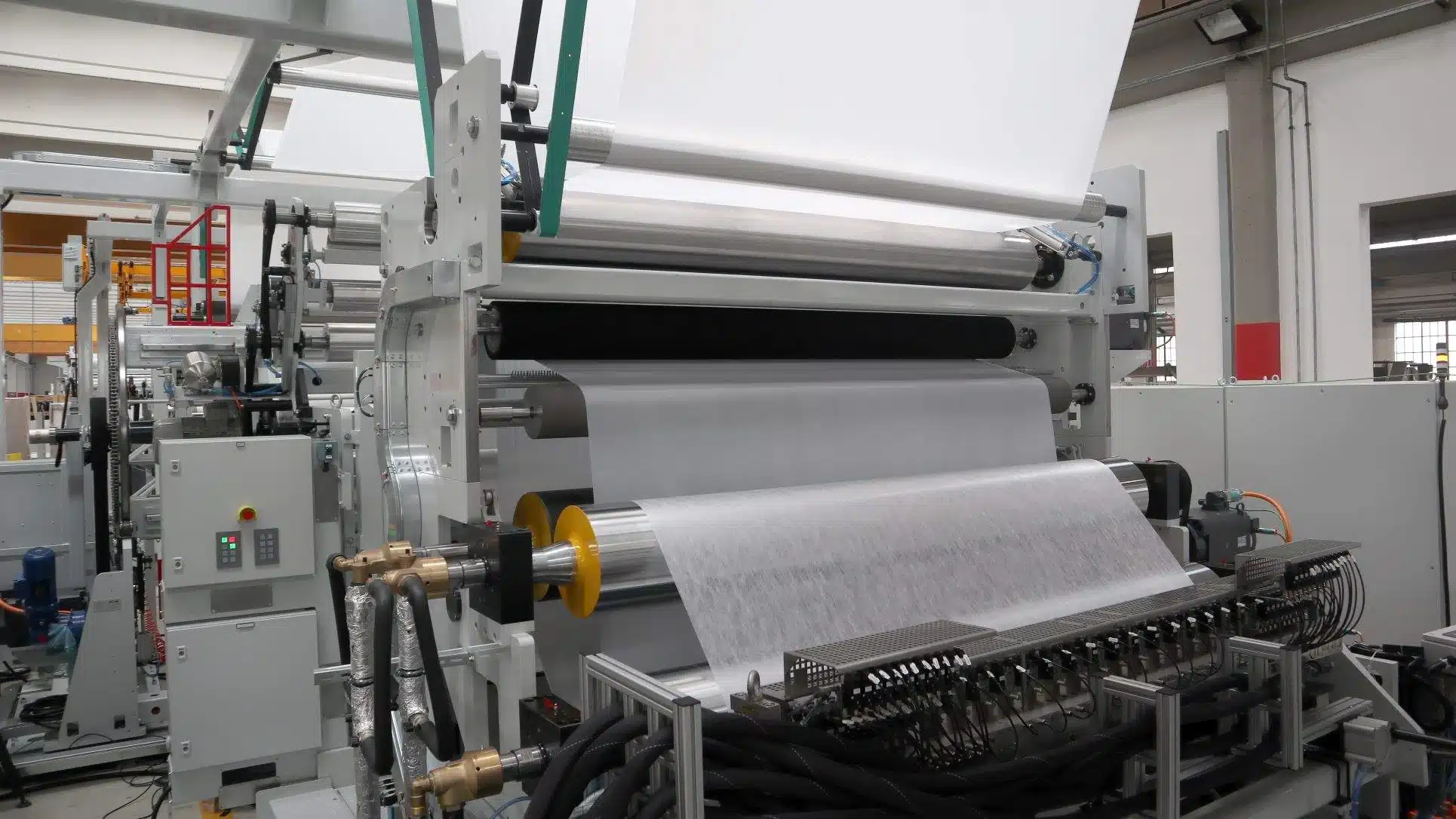

Features that we find in the A.Celli F-LINE® complete turnkey lamination lines, designed to perform high quality adhesive, thermal and ultrasonic laminations. Equipped with unwinding and laminating stations and an in-line slitting section, it is capable of laminating two or more layers with a maximum web width of 3,600 mm at a maximum operating speed of 400/800 m/min.

To this is added the ability of A.Celli to integrate the data of the upstream machines with those downstream, thus obtaining a perfect tracking of the finished reels and of the single process phases that led to its formation.

Finally, A.Celli is able to offer, as an option, a perfect integration of the flexographic printer with the lamination line. In this case, the IRIDIUM® flexo printer will be positioned inside the lamination line, between the unwinder and the lamination section itself, offering you the possibility of:

- Managing the print repeat length directly on the finished product, right after the printing phase is completed

- Laminating with tighter tolerances than would be expected when laminating previously printed rolls.

- Avoid the use of an unwinder and a winder, respectively before and after the flexographic printing machine, and the consequent handling of reels between two off-line machines.

Do you want to find out more about the complete range of A.Celli solutions for the end of line? Download our free eBook “A.Celli end-of-line solutions for nonwovens production”!