It also helps that the content of the label can be directly compared with the data present in the company ERP, thus being able to accurately verify whether the reel or bundle reflect all the customer’s requests.

However, the information contained in the virtual label also goes beyond the minimum information collected by a physical label with legal value, allowing for complete traceability of the entire production process.

In fact, by eliminating the intrinsic problem of the standard label, that is the limited physical space that we can use, we can fill in an endless number of fields, reporting in detail how the checks were carried out during each production phase, if the quality has not undergone alterations and also which operator followed the production of the reel and in which phase. This, in the case of any contamination or defects, allows to establish the causes and attribute the due responsibilities.

In practice, the information contained in the virtual label is a certification of the quality of the finished product, an essential requirement for nonwoven intended for use in the medical and hygienic fields.

All this information can then be obtained by the operator or a field supervisor, by scanning the barcode on the paper label or “reading” an RFID chip inside the same label.

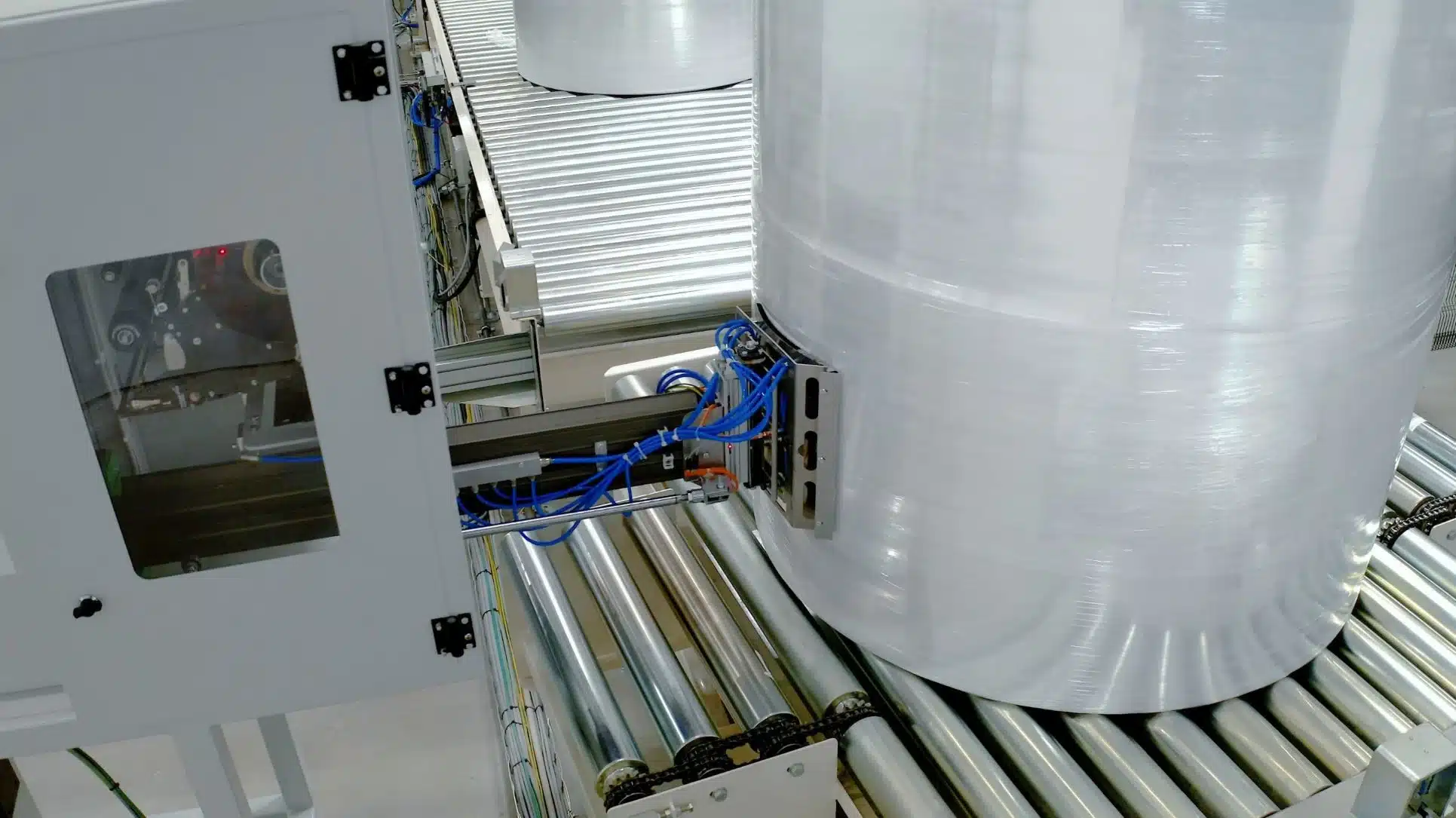

Some automatic packaging systems, like the ones offered by A.Celli, also allow you to check the consistency between the processes performed by the packaging line and the final result of the process in terms of package composition. This is thanks to the presence of a 3D visualization system, installed along the packaging line, capable of scanning the labels applied on the cores, on the external surface of the reels and on the bundles at the end of the process.

A further comparison between the information contained in the labels and those entered in the ERP will allow to verify the actual consistency.

The “legal” value of traceability

The direct connection with the company ERP of the system that manages the movement of the reel or bundle allows you to store and organize all the data obtained during production.

In this way, the entire history of the reel or bundle is traced, from the production of the raw material and the finished product to the shipment to the customer. This means having extremely detailed traceability, which allows you to accurately certify the quality and origin of the reel itself.

This aspect can be fundamental if disputes arise with the customer. It helps to manage any complaints with professionalism, certainty of the data and speed in the response and in the production of arguments to support our case.

The detailed traceability in fact allows you to accurately establish, for example, what the state of the reel was when it was in the dispatching area, at what time it was loaded on the means of transport and when it left the production plant.