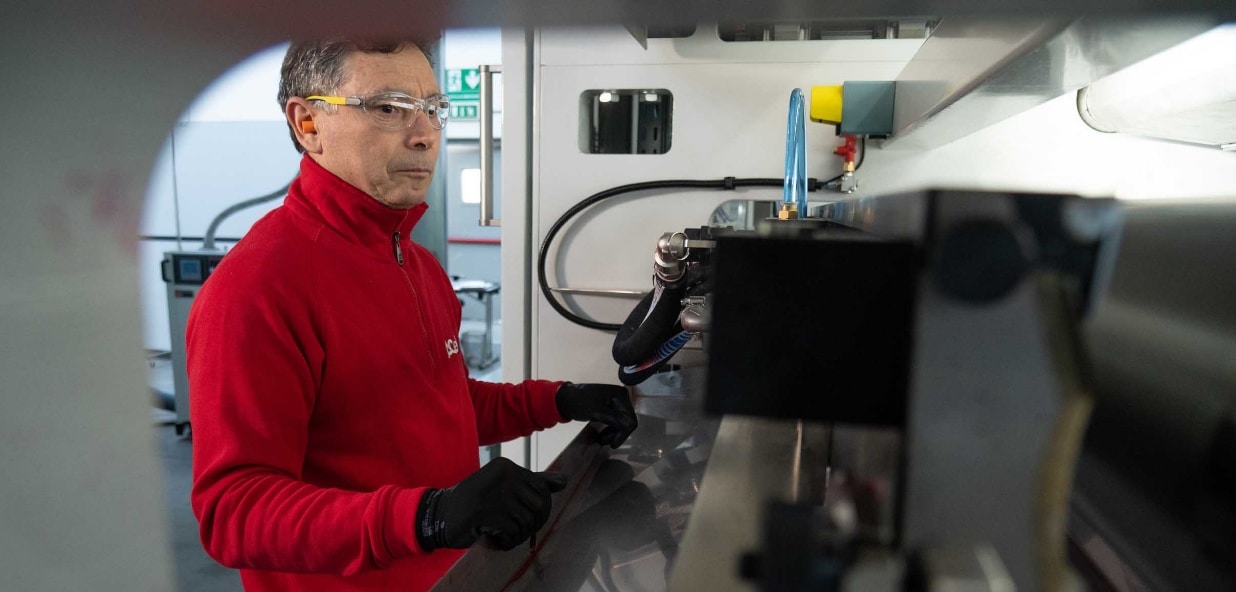

A.Celli can count on a department dedicated to nonwoven, machinery retrofitting made up of senior mechanical and automation engineers available for technical consultations, equipment inspections and software and equipment updates.

These are some examples of what A.Celli can do to update or retrofit your existing machines and systems:

- Install new, high-efficiency motors equipped with software for energy monitoring

- Upgrade to Slittomatic® – a longitudinal cutting system that ensures high-quality production and reduces the positioning time of the slitting units (it is possible to position 45 slitting units in 2 minutes with the highest precision)

- Custom-designed systems to reduce the dust originated by the slitting processes in the rewinding section

- Fully automated roll ejector and core loading systems suitable for working with both tissue and cardboard

- Change the operation of the machine from manual to automatic

- Winding upgrades that include upgrades to slitting, drives and much more