Predictive maintenance and scheduled interventions

Today’s technology allows for the automation of the monitoring previously performed by people, which is the foundation of proactive maintenance. This results in even more efficient and accurate control through what is known as predictive maintenance, which can be achieved through a high level of automation in the production line and the integration of Industry 4.0 features, such as sensors and IoT.

These technologies allow for real-time monitoring of the machine’s operation, giving control over the production capacity and the state of the various components. In fact, predictive maintenance makes it possible to establish with a high degree of precision if and where failures may occur, or if a component is nearing the end of its useful life. It is thus possible to act in advance to carry out the necessary interventions aimed at avoiding a sudden interruption of the activity, maintaining a production line in optimal conditions.

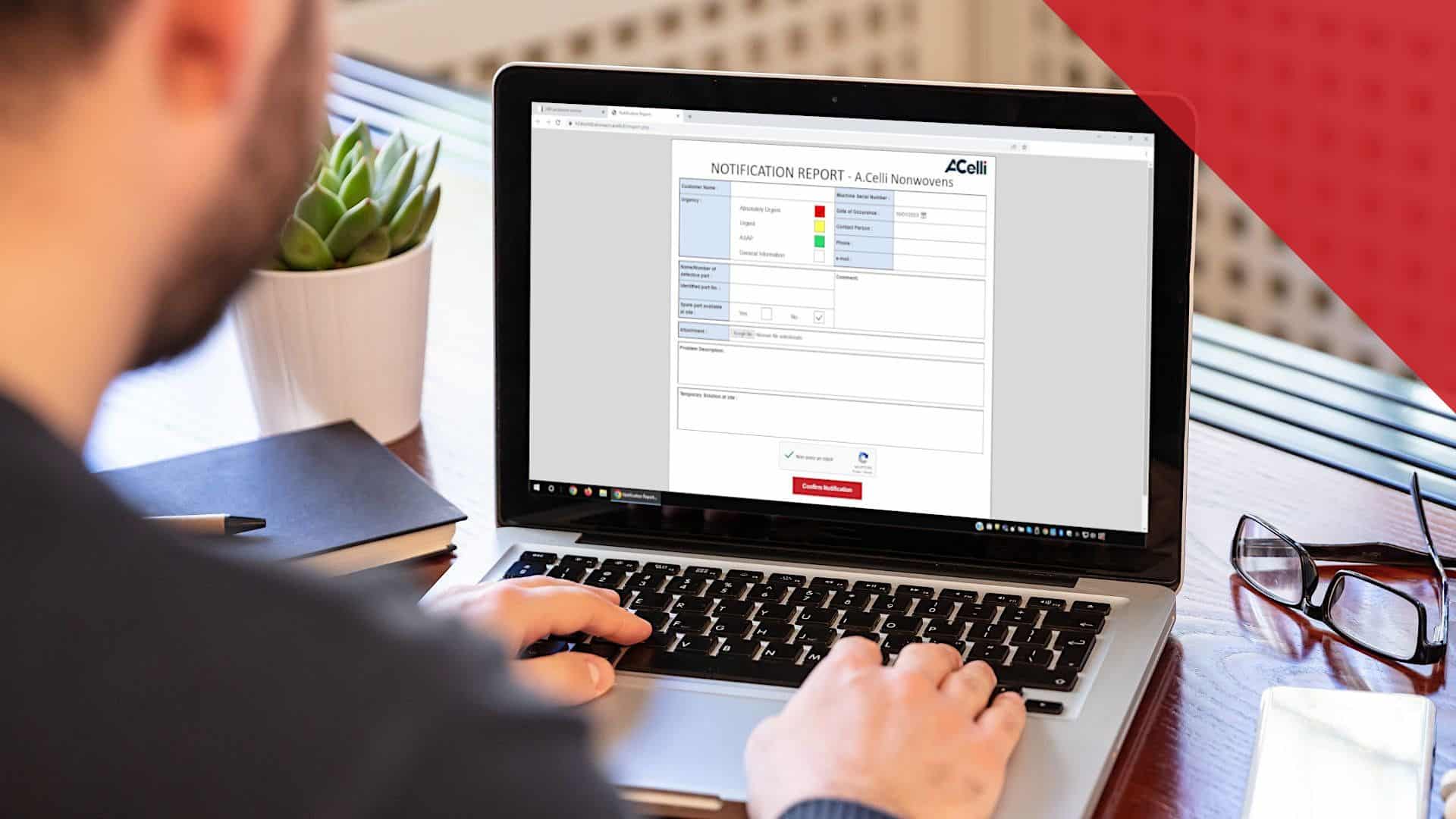

However, due to the characteristics of individual facilities, predictive maintenance may not always be possible. For this reason, and to reduce the duration of scheduled machine shutdowns while preventing unexpected ones, A.Celli also offers the option to subscribe to specific maintenance plans, a service offered for both new machinery and those already installed.

Of course, in the case of machinery that has been in use for some time, a team of specialized technicians must analyze the plant and all its components, the customer’s production needs and the machine’s history, in order to assess its conditions. At that point (and in the case of new machinery, for which an inspection is obviously not necessary), the customer will receive a detailed description of the interventions that A.Celli technicians will need to perform during the subsequent scheduled machine shutdowns, along with a list of parts that will need to be periodically replaced with original spare parts to ensure proper plant operation and maximum performance over time.