Savings in key areas include:

- Maintenance and repair

- Manual labor

- Waste of raw materials and final product

- Energy usage

- Productivity

There are a few process on the production line that are ideally suited to industrial automation. These would normally require people to perform manual labor that takes time, effort and precision, often resulting in error and reduced productivity. This is human labor that would be better used elsewhere. With that in mind, let’s take a look at the best industrial automation upgrades.

5 components that can benefit from industrial automation

1. Unwinder

The automation of the unwinder is specific to the web tension control system. In conventional web control systems, the tension is controlled by the difference in speed between motorized parts in relation to the Master Roll (winder) and this leads to speed differences between contiguous motorized organs. This system requires frequent manual adjustments to maintain sub-optimal web tension.

With the automation of the unwinder, an additional roller is placed at the exit of the unwinding machine, below which is placed a load cell. The two exit rollers still act in coordination with the movement of the flat belts system. However, web tension is automatically measured by the load cell, which is sensitive enough to detect minute variations in web tension, and controlled by the software.

The benefits of this upgrade are:

- Reduced bulk loss

- Product quality improvement

- Reduced need for manual tension adjustments

- Reduced occurrence of human error

- Minimized wasted time

- Production increase

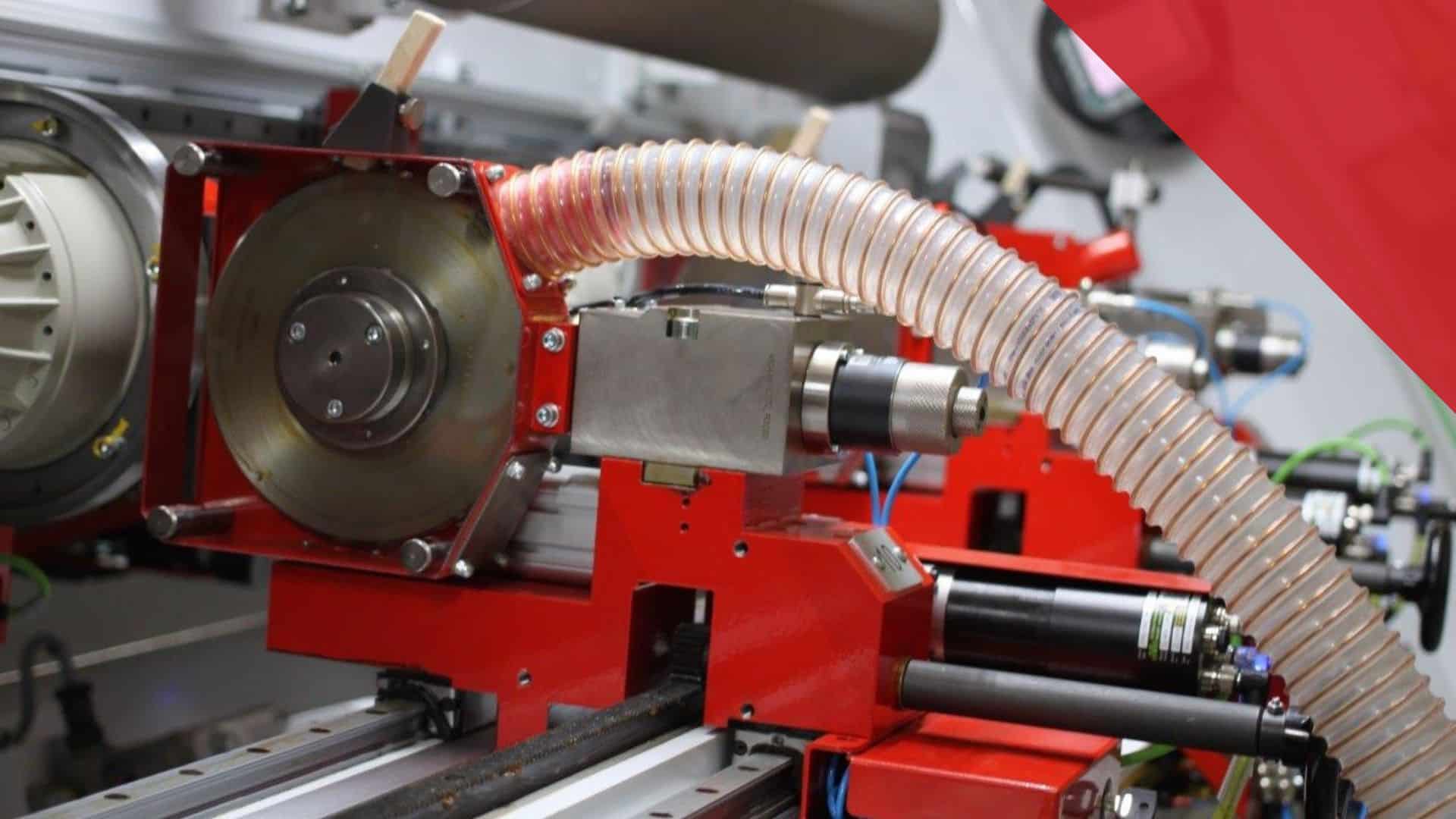

2. Slitting section

An upgrade to automate the slitting system provides revolutionary improvements in the precision of the machine. The automated system simplifies the precise positioning of the knives and counter-knives during the slitting process.

This upgrade comes with proprietary software with a user-friendly interface that stores the knife settings and makes it easy for the operator to adjust those settings as needed.

This upgrade can made on an existing slitter rewinder with minimal or no structural modifications to the machine. The automation system is fully assembled prior to installation, which minimizes the amount of downtime needed.

The alternative to upgrading an existing system is to switch to A.Celli’s SLITTOMATIC®.