Defects resulting from incorrect winding and rewinding processes

As mentioned in the opening of the article, errors in the winding and rewinding processes can affect the quality of the nonwoven fabric obtained in the upstream forming line. An incorrect setting of the process parameters can, in fact, give rise to numerous defects. Let’s see together the main of these, highlighting the cause.

Excessive tension

If during the winding and rewinding phases we use too high web tension values, we will create excessively compact reels which could have the following defects:

- Loss of product bulk

- Crushed core

- Corrugations: bands of relatively uniform width and equidistant from the edges, characterized by diagonal marks within them and located all around the reel.

Crepe wrinkles: wrinkles in the machine direction at an angle with respect to the axis of the roll; they are weak points that can lead to the breaking of the web

LOOSE TENSION

While excessive tension is definitely to be avoided for the above reasons, using too low a tension value can also lead to numerous problems, including:

- Egg shaped roll

- Reel with flat spots: when the reel is excessively soft and not very compact, the external surface could have a flattened section, even following inaccurate handling operations

- Loose core: if the core rotates at a different speed than the surrounding reel. The rotational displacement may cause the nonwoven web to separate from the core

- Irregular reel profile

- Telescoped roll: a progressive roll edge misalignment due to the slippage of the layers in machine or cross direction. The resulting reels have a concave or convex profile

Taper function setting errors

If, during the winding and rewinding processes, the tension (and, if necessary, the nip and torque) is not reduced as the diameter of the reel increases (taper function), we can encounter, for examples, problems relating to the profile such as telescoping or starring (the presence of a “star” pattern).

Specific defects of the rewinding phase

Rewinding is an extremely delicate phase of the process: from here the finished reels will come out which, in the event of significant defects, could be discarded, leading to loss of material and money. In addition to the defects described above, there are some that are characteristic of the rewinding phase and to which particular attention must be paid:

- Overlapped reels: defect resulting from the overlapping of contiguous strips of material during rewinding

- Defects related to the slitting phase, which can lead to rough and fuzzy roll edges or to the presence of trimmings not properly removed inside the reel

Finally, especially in the case of nonwovens intended for the hygienic-sanitary market, it is absolutely necessary to avoid contamination of the finished rolls by external agents such as dust (resulting from the cutting phase), oil and grease.

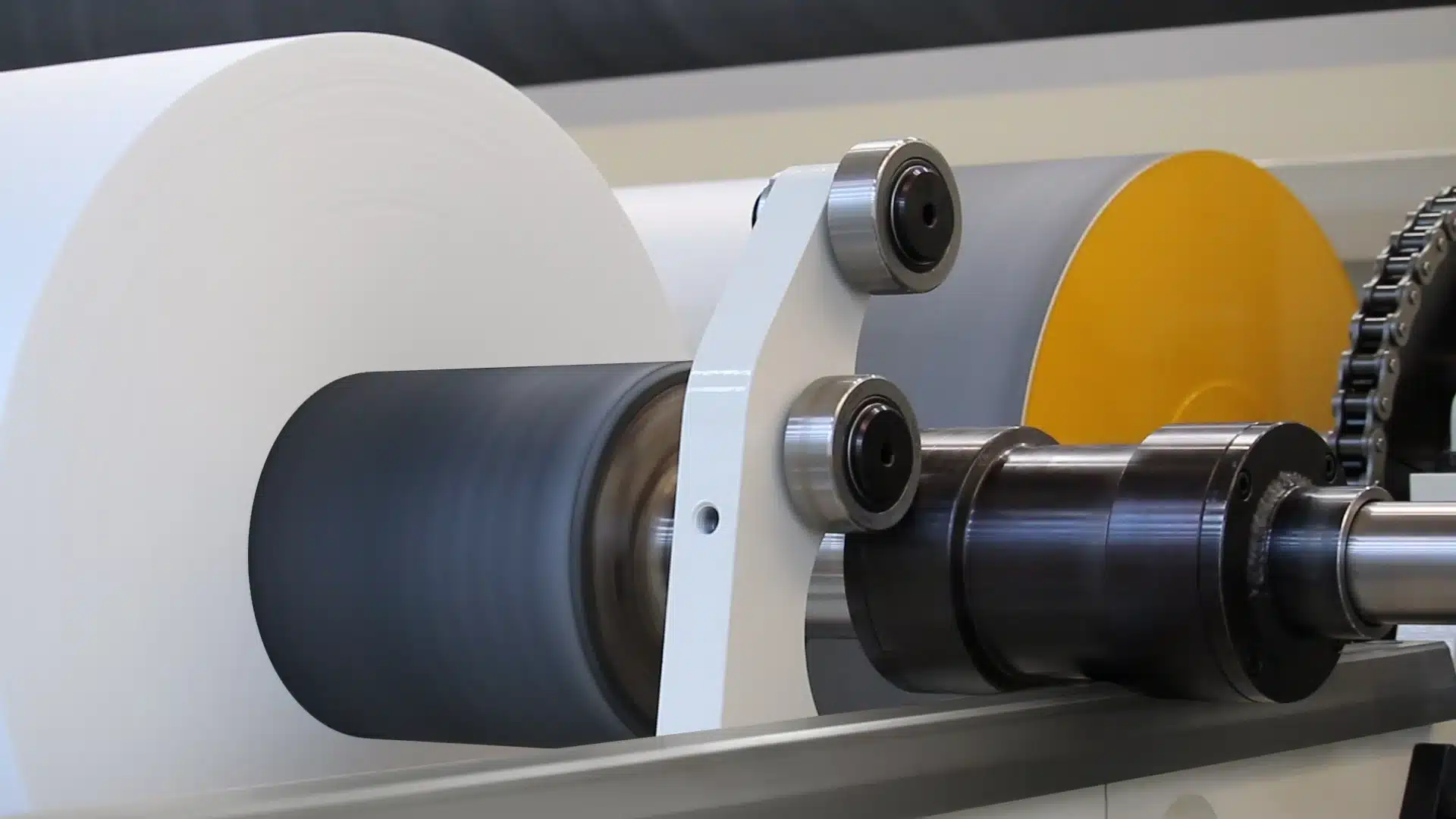

Obtain perfect reels using A.Celli E-WIND® solutions

Considering the issues we have just listed, there is only one way to ensure that these processes take place in an optimal manner: using machinery of absolute reliability and quality. Through the E-WIND® product line, A.Celli offers a wide range of solutions that allow you to better manage the end-of-line of your nonwoven production plant, from winding to rewinding.

Entering more in detail, the E-WIND® range allows you to obtain a high final quality of the reels for any type of nonwoven fabric, from standard products, such as spunbond and spunlace, to innovative materials such as high loft nonwovens, which require particular precautions and specific machinery in order to preserve their intrinsic characteristics.

The increase in productivity deriving from the optimization of machine cycle times guaranteed by our machinery should also be emphasized. Operations such as master roll change, knives positioning (which can be carried out through our patented automatic system Slittomatic®), finished reel change cycle, defects management and, generally, the collection of activities which occur when the machine is stopped, are in fact carried out with maximum efficiency.

The A.Celli E-WIND® range allows you to achieve total digital integration of the end-of-line with all upstream and downstream machines, in order to ensure perfect product traceability. Added to this are 3D models via HMI, intuitive diagnostic tools and safety systems developed and implemented following customized risk analysis activities.

Conclusions

Here ends the first stage of the journey of a nonwoven reel. While waiting for the next article, in which we will examine in detail the lamination and flexographic printing phases, why not download our free eBook “A.Celli end-of-line solutions for nonwovens production”? You will surely find the solution that best suits your needs!