The definition provided by INDA only describes the principle behind the production of nonwoven. Indeed, a variation in fibre selection, web formation, bonding and finishing creates products with their own characteristics and vastly different one from the other. This makes them suitable for use in numerous areas, such as hygiene-sanitary market, clothing, automotive, filtration, building and agriculture.

We can divide the technologies currently used to produce nonwoven into six types:

Airlaid

This method uses air to form a homogenous web composed by short fibres randomly oriented. The subsequent bonding of the fibres, deposited onto a conveyor belt permeable to air, can take place by using heat (TBAL), hydrogen (HBAL), latex (LBAL) or a mixed LBAL + TBAL process.

Air-through bonding

A thermal bonding process which involves the use of heated air on the surface of the nonwoven material, giving life to a bulky, soft, uniform material with a high resistance to traction. This process does not use chemical binders and it is the only type of thermal bonding process that submits the entire product to a uniform temperature.

Meltblown

Nonwoven obtained using a spinning process called “blow spinning”. The melted polymeric fibres are passed through a a spinneret to form long thin fibres, which are then stretched and deposited on a conveyor belt using hot compressed air, thus creating the web. Meltblown nonwoven are composed of extremely long, light-weight fibres and have high filtering capacities.

Spunlace

Nonwoven obtained using a bonding process for moist or dry fibrous webs obtained using carding, air-laying or wet-laying. The process, known as spunlace or “hydroentanglement”, uses fine jets of water at high pressure that penetrate the web, hit the conveyor belt and bounce against it, thus causing the entanglement of the fibers.

Spunlaid (or Spunbond)

Spunlaid nonwoven (also called spunbond) are materials composed of extremely thin filaments. They are produced using a process that includes extrusion of polymers to form continuous filaments, which will be later conditioned, stretched and deposited onto a conveyor belt to create the web. The filaments will be chemically, mechanically, or thermally bonded to obtain the end product. Spunbond based on polypropylene is the predominant material for diapers and female hygiene products, as well as medical clothing.

Spunmelt/SMS

The spunbond is often combined with meltblown nonwoven to create a layered product called SMS (spun-melt-spun). Made completely in PP, the SMS nonwoven are water repellent and can be used for disposable applications. Meltblown is often used as a filter material due to its ability to capture very fine particles.

Wetlaid

Production technology similar to the one used in paper production. Nonwoven of this kind are distinguished from wetlaid paper because more than 30% in weight of their fibrous content is formed by fibres with a length/diameter ratio greater than 300, while the density is lower than 0.40 g/cm3. Wetlaid is commonly used to manufacture products such as tea bags, coffee filters and disposable wipes.

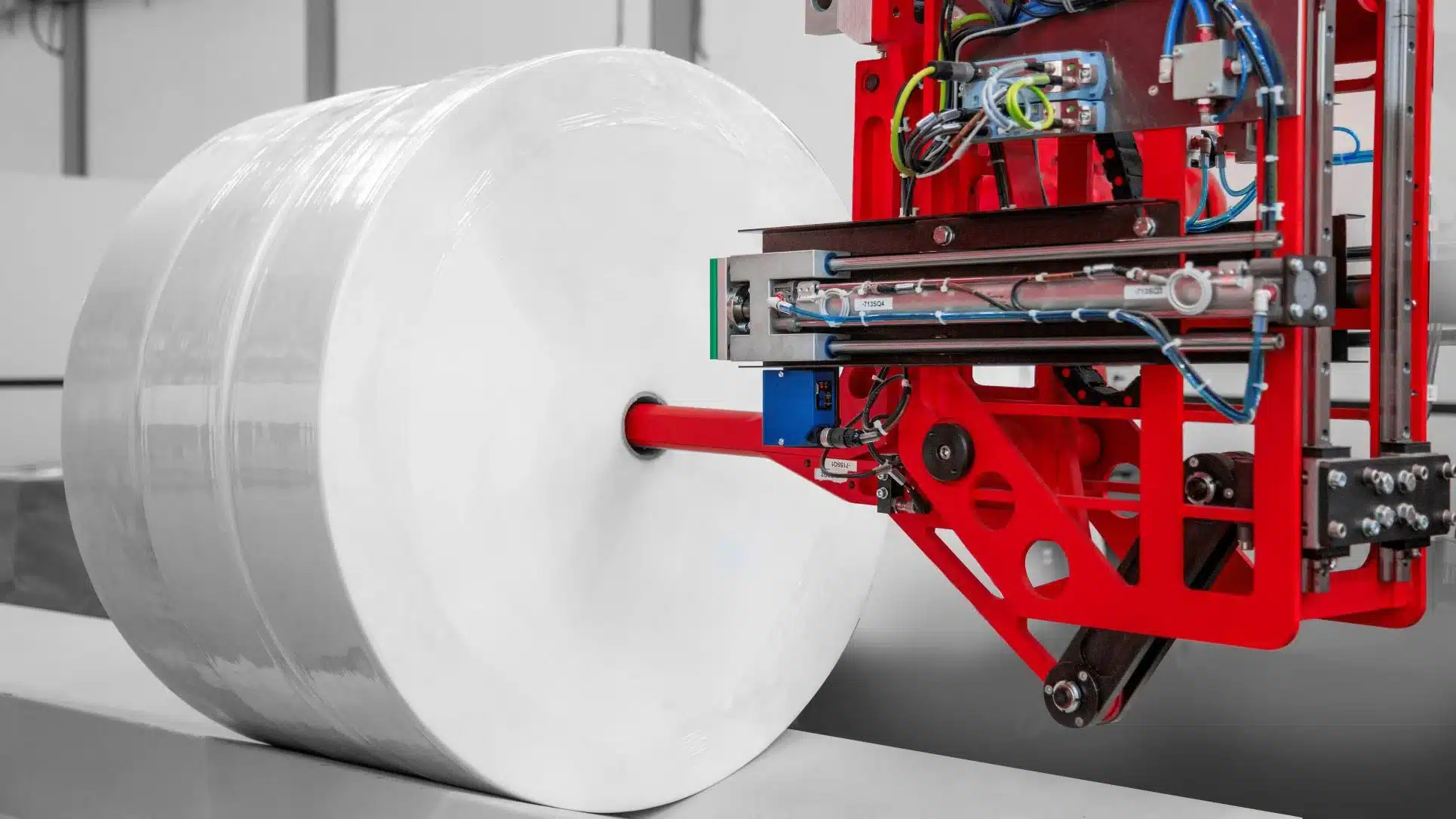

Among the key characteristics of nonwoven materials we can also find the elasticity, which leads to a progressive shrinking of the starting width of the web (neck-in) from the winding phase to the final product. In this regard, it is necessary to distinguish the specific characteristics of the two main types of nonwoven: spunlaid and spunlace.

Spunlaid, characterised by a random positioning of its fibres, it is more resistant to traction and, for this reason, it is subject to greater shrinking compared to spunlace. An initial web width of 3600 mm, for example, leads to final reels with a width equal to 3200 mm.

Spunlace, on the other hand, is composed by fibers oriented in Machine Direction (MD), due to the use of carding machines in the formation process. This makes it resistant to traction in that direction and, therefore, less prone to shrinkage.